This article originally appeared in a 2004 edition of the Wisconsin Maple News.

Plastic tubing and vacuum pumping continue to grow in popularity in Wisconsin sugarbushes with a few more miles added every year. But long before the invention of plastic tubing in the late 1950s, early twentieth century Yankee farmers wanting to reduce the labor of gathering sap invented a metal gravity-fed pipeline system that carried sap directly from the tree to the sugarhouse. This metal pipeline system consisted of three sizes of tubing, each constructed from long narrow sheets of English tin folded and crimped at the top and slightly tapered at the end to be inserted tightly into another piece of tubing. The system also included spiles made from conical sheets of tin with a metal tube soldered to the bottom like a drop line. The spile was either inserted directly into openings on the top of pipeline or into connecting pieces that fit into the pipeline. This connection from the spile to the tubing was made by a shorter, tapered piece of tubing with a curve at the narrow end, similar in appearance to the neck of a goose. In fact, it was this piece that gave this system its common name of “gooseneck system”. The weight of the rigid metal pipeline was supported by heavy gauge wire strung through the woods, with a hook at one end of each piece of tubing to hang the tubing on the support wires.

The gooseneck system was patented in 1916 near the village of Mayfield, New York along the southern margins of Adirondack State Park by William H. Brower, Jr. Brower, who was described by his grandson as a mechanic and tinkerer, developed the system with his neighbor and syrup maker, Edward L. Lent. Today, the workshop where it was invented still stands on land owned by the Lent family and is noted by a roadside historic marker. According to Lent family history, Brower and Lent later sold the patent to one of the larger Vermont maple syrup equipment makers. Amazingly, through four generations of syrup making, the Lent family has never stopped using the gooseneck system. At one time, the Lent family’s mountainside sugarbush was using as many as 2500 taps on the system and boiling on a 3 foot by 16 foot wood fired evaporator. In recent year the family has reduced their tapping to around 300 to 400 taps and downsized to a 2 foot by 10 foot evaporator. According to the Lent family, the metal pipeline will occasionally freeze during cold spells, but thaws out quickly on south and east facing hillside of the their sugarbush. At the end of the season, the network of support wire is left strung through the sugarbush but the tubing is taken down. The pipeline sections are washed and boiled in the evaporator in the last sap of the year then set upright to dry, coating them with a thin layer of sugary sap that prevents rust from developing in the off season.

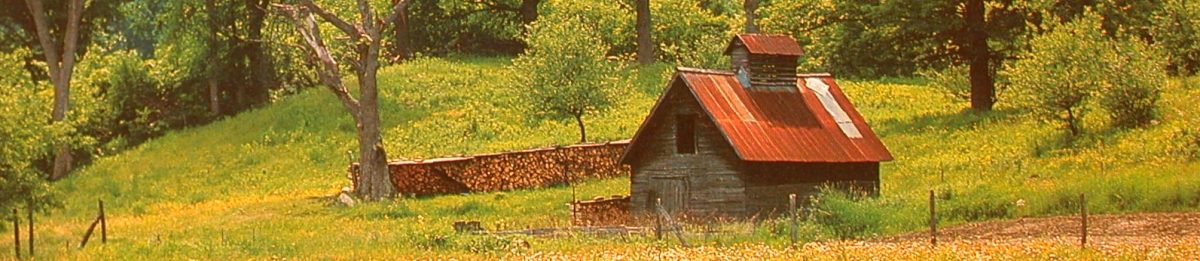

The gooseneck system was sporadically used during the 1920s and 1930s in the more hilly and mountainous sugarbushes of northeastern United States. Until recently, this technology was not known to have made it as far west as Wisconsin. However, in 2003, cultural resource management staff of the USDA Forest Service in Wisconsin discovered the long abandoned remains of a maple sugaring operation in the hills of southwestern Ashland County. The remains of this former sugarhouse and storage building included over one thousand, four-foot long sections of the tubing system, as well as the gooseneck connecting pieces, coils of suspension wire and other debris. Today the site appears as a series of building foundations in an overgrown clearing at the base of a maple covered ridge, a perfect location of the gravity fed pipeline system.

Based on the age of the other artifacts at the site, including three sizes of metal syrup tins, the use of this sugarbush roughly dates to between 1915 and 1930. The U.S. Forest Service acquired the land in 1934, shortly after it had been logged and most of the large mature maple trees removed. As the only known example of the use of the gooseneck system in Wisconsin, the Forest Service has recognized its historical importance and is protecting the site as part of planned forest management activities. In addition, research into the history of the site and use of the pipeline continues.