This article originally appeared in a 2005 edition of the Wisconsin Maple News.

The 1940s and 1950s were a time of invention and innovation in the maple industry. One of the innovations brought to the industry by Wisconsin was the Central Evaporator Plant. Initiated by Wisconsin’s own Maple King, Adin Reynolds, the Central Evaporator Plant operated like a cheese factory in which maple sap, like milk, was transported from a variety of sap producers to a large processing facility where sap was combined and converted into maple syrup. As with the cheese factory where milk producers were paid based on the butterfat content of their milk, sap producers were paid based on the sugar content of their sap.

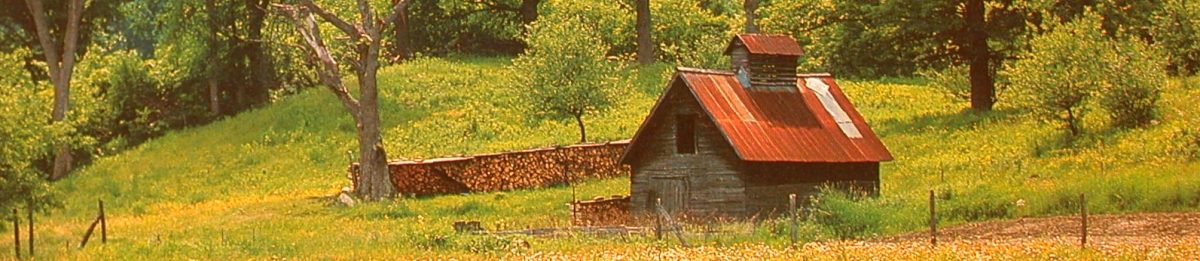

The Reynolds family had always been maple producers, making syrup and sugar from maple trees in their own sugarbush. But in 1946, Adin Reynolds decided to greatly expand his production and he had a novel idea how to do it. He began in 1947 by building a new sugarhouse next to his house, not far from State Highway 45. He then solicited farmers near his Antigo home to tap their maple woods for sap and deliver it to his sugarhouse, where they were paid based on the percentage of sugar per gallon of sap.

According to his son, Juan Reynolds, Adin had no problem convincing area farmers to sell their sap. Located near the intersection of Langlade, Shawano and Marathon Counties, the countryside around the Aniwa plant is marked with dairy farms interspersed between stands of second growth sugar maples. Moreover, the months of March and April were the slow and muddy seasons for most farm families. Farmers had the two most important components for sap production – trees and available labor to tap and gather.

Reynolds’ Aniwa operation quickly grew, expanding from two to three evaporators in 1949 to four evaporators in 1962 making syrup from 75,000 taps. Other maple producers followed Reynolds’ lead, and with his advice and equipment sales set up their own Central Evaporator Plants in the area. Notable among these were plants run by George Klement in Polar and Sidney Maas in Tilleda. Reynolds later purchased the Polar and Tilleda plants, along with another Central Evaporator Plant in Kingsley, Michigan. At their peak in the mid-1960s, the Reynolds Sugarbush was making 30 to 40,000 gallons of syrup a year from at least 160,000 taps on 14 evaporators in these four Central Evaporator Plants.

Another Central Evaporator Plant went into operation in 1962 in Price County near the village of Ogema. Ray Norlin and his brother-in-law Louis Motley expanded their small operation to 2800 taps and began to buy sap from 7,000 more taps making as much as 3000 gallons of syrup a year. A portion of this syrup was sold in bottles and cans under the label Sunny Hills Maple Syrup; however, the bulk of it was sold wholesale in barrels to Reynolds Sugarbush.

Although he was the most successful Central Evaporation Plant operator, Adin Reynolds was not necessarily the first maple producer to buy large volumes of sap in the late 1940s and early 1950s. To the west in Central Minnesota, the Holbert Brothers also instigated a sap buying program in 2947 for their Mille Lacs Maple Products Company. Although the sap buying and syrup making portion of his business was short lived, ending in 1950, Sherman Holbert’s operation was very large for the time, processing sap on two large evaporators from as many as 20,000 taps in the Mille Lacs Lake region. Holbert also developed a Midwestern market by buying large volumes of bulk syrup to be sold to General Foods for the Log Cabin brand of blended syrup. Holbert left the maple business entirely by 1953, opening the door for the Reynolds Sugarbush to assume the large General Foods bulk syrup contracts.

Over the course of the 1950s word of the Central Evaporator Plant and its successes in Wisconsin spread among maple producers in the northeast and New England states. In the traditionally larger maple producing states like Vermont, New York, and Pennsylvania, sap buying was generally unheard of at the time, especially on the scale being carried out in Wisconsin. But by the 1960s, , the Central Evaporator Plant, along with plastic tubing and the invention of the antibacterial paraformaldehyde tap hole pellet, was one of the hot topics of discussion among industry leaders. In fact, C.O. Willits, the maple syrup industry’s leading researcher wrote that “the current trend toward central evaporator plants has marked a new era in the maple industry”.

The growth of the Reynolds Sugarbush empire and the purchase of additional Central Evaporator Plants in 1960, 1963, and 1965 was in large part a result of the contract Reynolds secured with General Foods Corporation in 1959 to supply thousands of gallons of syrup for the making of Log Cabin brand table syrup. In order to meet General Foods demand, Reynolds Sugarbush produced tens of thousands of gallons of syrup and purchased many times more gallons of bulk syrup from Wisconsin producers and across the maple producing regions of the United States and Canada.

Through the 1950s and 1960s, the popularity of the Central Evaporator Plants, along with Reynolds Sugarbush’s promotional efforts and syrup buying program led to a significant increase in the production of maple syrup in Wisconsin. Production grew so much that, by 1970, Wisconsin moved into position as the third greatest syrup producing state behind Vermont and New York. It comes as no surprise that the idea for the Central Evaporator Plant was born in Wisconsin. As the most prominent dairy state in the country, most of Wisconsin’s rural residents in the 1950s and 1960s were familiar with the organization of the dairy industry and cheese factories and took to the concept readily. Likewise, many sap producers were dairy farmers and had both the equipment and technical knowledge needed for moving large volumes of perishable sap.

Reynolds later closed the Polar plant and sold the Kingsley, Michigan and Tilleda plants back their owners in the early 1970s. Sidney Maas continued to operate the Tilleda sugarhouse as a Central Evaporator Plant through the 1980s on sap from 8200 of his own taps and sap purchased from 5000 additional taps. In 1993 Maas sold the sugarhouse to Charlie Wagner who had developed a successful syrup operation near his home in Peshtigo and wanted to expand. Aware of the sap buying history of the operation and the available sap resources in the area, Wagner revised the sap buying program, convincing many of the earlier sap producing families under the Reynolds era to again tap their trees and sell their sap. Today, the Tilleda plant uses reverse osmosis and two large oil fired evaporators to make syrup from as many as 40,000 taps, over 90 percent of which is purchased sap. The Tilleda plant is particularly notable in the history of Wisconsin maple production. With nearly continuous syrup production since Sidney Maas built the sugar house in the 1940s, the Tilleda sugarhouse has the honor of being one of the oldest continually used sugar houses in Wisconsin, it is one of the largest U.S. sugarhouses by volume west of Maine. In addition, it is probably the oldest Central Evaporator Plant still in operation in North America.

Only a handful of sugarhouses that follow the plan of a Central Evaporator Plant operating primarily or entirely on purchased sap, still exist in the U.S. However it is not uncommon for commercial producers to augment their own sap supplies with some sap purchased from neighbors and reliable sap producers, ultimately the result of an idea that began over fifty years ago in Wisconsin.